Code: Tipo B

Clamps

| Lega | BxS Dimensione | Peso al metro |

|---|---|---|

| 0 | [[part1]] | [[part2]] |

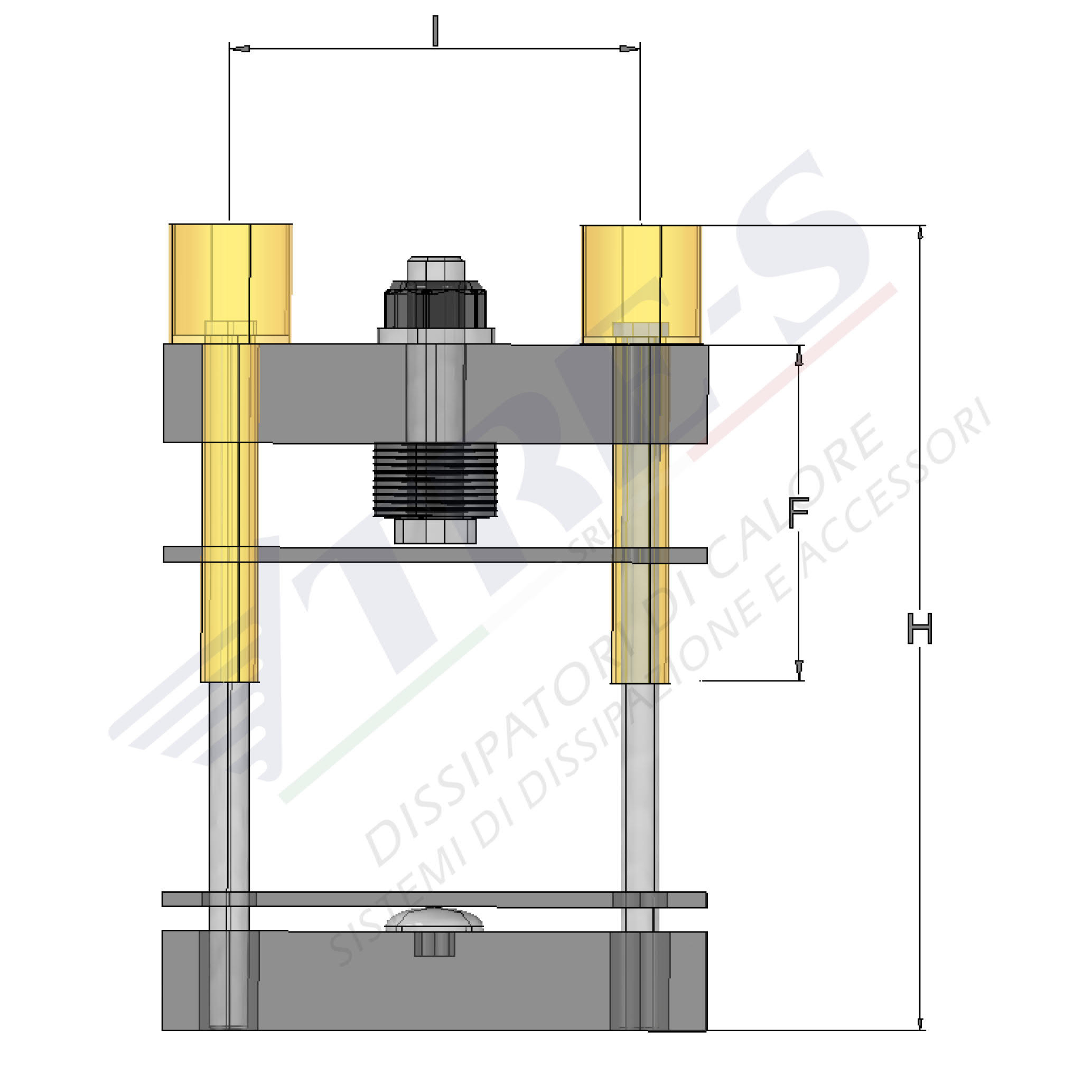

| Codice | KN MAX | I | F | H |

|---|---|---|---|---|

| KL70B/30 | 13 | 70 | 30 | 107 |

| KL70B/40 | 13 | 70 | 40 | 117 |

| KL70B/50 | 13 | 70 | 50 | 127 |

| KL70B/60 | 13 | 70 | 60 | 137 |

| KL70B/70 | 13 | 70 | 70 | 147 |

| KL70B/80 | 13 | 70 | 80 | 157 |

| KL70B/90 | 13 | 70 | 90 | 167 |

| KL70B/100 | 13 | 70 | 100 | 177 |

| KL70B/110 | 13 | 70 | 110 | 187 |

| Codice | KN MAX | I | F | H |

|---|---|---|---|---|

| KL79B/30 | 20 | 79 | 30 | 108 |

| KL79B/40 | 20 | 79 | 40 | 118 |

| KL79B/50 | 20 | 79 | 50 | 128 |

| KL79B/60 | 20 | 79 | 60 | 138 |

| KL79B/70 | 20 | 79 | 70 | 148 |

| KL79B/80 | 20 | 79 | 80 | 158 |

| KL79B/90 | 20 | 79 | 90 | 168 |

| KL79B/100 | 20 | 79 | 100 | 178 |

| KL79B/110 | 20 | 79 | 110 | 188 |

| Codice | KN MAX | I | F | H |

|---|---|---|---|---|

| KL89B/30 | 25 | 89 | 30 | 109 |

| KL89B/40 | 25 | 89 | 40 | 119 |

| KL89B/50 | 25 | 89 | 50 | 129 |

| KL89B/60 | 25 | 89 | 60 | 139 |

| KL89B/70 | 25 | 89 | 70 | 149 |

| KL89B/80 | 25 | 89 | 80 | 159 |

| KL89B/90 | 25 | 89 | 90 | 169 |

| KL89B/100 | 25 | 89 | 100 | 179 |

| KL89B/110 | 25 | 89 | 110 | 189 |

| Codice | KN MAX | I | F | H |

|---|---|---|---|---|

| KL102B/30 | 30 | 102 | 30 | 125 |

| KL102B/40 | 30 | 102 | 40 | 135 |

| KL102B/50 | 30 | 102 | 50 | 145 |

| KL102B/60 | 30 | 102 | 60 | 155 |

| KL102B/70 | 30 | 102 | 70 | 165 |

| KL102B/80 | 30 | 102 | 80 | 175 |

| KL102B/90 | 30 | 102 | 90 | 185 |

| KL102B/100 | 30 | 102 | 100 | 195 |

| KL102B/110 | 30 | 102 | 110 | 205 |

| Codice | KN MAX | I | F | H |

|---|---|---|---|---|

| KL118B/30 | 40 | 118 | 30 | 136 |

| KL118B/40 | 40 | 118 | 40 | 146 |

| KL118B/50 | 40 | 118 | 50 | 156 |

| KL118B/60 | 40 | 118 | 60 | 166 |

| KL118B/70 | 40 | 118 | 70 | 176 |

| KL118B/80 | 40 | 118 | 80 | 186 |

| KL118B/90 | 40 | 118 | 90 | 196 |

| KL118B/100 | 40 | 118 | 100 | 206 |

| KL118B/110 | 40 | 118 | 110 | 216 |

| Codice | KN MAX | I | F | H |

|---|---|---|---|---|

| KL140B/30 | 50 | 140 | 30 | 180 |

| KL140B/40 | 50 | 140 | 40 | 190 |

| KL140B/50 | 50 | 140 | 50 | 200 |

| KL140B/60 | 50 | 140 | 60 | 210 |

| KL140B/70 | 50 | 140 | 70 | 220 |

| KL140B/80 | 50 | 140 | 80 | 230 |

| KL140B/90 | 50 | 140 | 90 | 240 |

| KL140B/100 | 50 | 140 | 100 | 250 |

| KL140B/110 | 50 | 140 | 110 | 260 |

Length: 0.00 mm

Weight: 0.00 kg/m

Weight A: 0.00 kg/m

Weight B: 0.00 kg/m

Height: 0.00 mm

Within this catalog, heat sinks are organized based on their shape and dimensions expressed in millimeters. Each profile is characterized by the following parameters:

- Weight: expressed in kilograms per meter of profile length (Kg/m).

- Length: indicated in millimeters and used for calculating thermal resistance (L).

- Width: also in millimeters, considered for calculating thermal resistance (°C/W), applicable only to high-efficiency heat sinks.

- Thermal Resistance in Natural Convection: expressed in °C/W with a temperature difference of 70°C (compared to an ambient temperature of 25°C).

- Thermal Resistance in Forced Convection: also expressed in °C/W, with an air velocity of 3 m/s and a temperature difference of 50°C.

The values of thermal resistance have been determined through a thermal simulation program designed to replicate realistic conditions. In particular:

- The heat source is uniformly distributed over approximately 50% of the dissipation surface, with central positioning on the heat sink.

- To maximize natural convection heat dissipation efficiency, the heat sink is designed with vertical fins. For horizontal installations, it is advisable to consider an increase of approximately 20% in thermal resistance.

- The surface of the heat sink is not subject to additional treatments.

Regarding black anodized heat sinks in natural convection, the thermal resistance is reduced by approximately 10%.

As the length of the heat sink increases, the thermal resistance decreases following a nonlinear law. The indicated values refer to the specified lengths; for different lengths, consult the “Length Correction Factor” graph to calculate the multiplication factor to be applied to the thermal resistance, both in natural and forced convection.